| |

|

|

|

Pioneers Since

1968 |

| Kerox ME-50,

Methyl Ethyl Ketone Peroxide (MEKP) Catalyst, was indigenously

researched, developed and pioneered by our late founder and visionary K.V.Ramanath. The FRP industry in India was begining

to take root in the mid 1960's and MEKP was being imported

from UK. Through R&D initiatives Kerox developed and

introduced the first indigenously developed MEKP product in

1968. Since then we have been the market leaders and

continue to innovate the technology and maintain the highest

quality standards.

|

|

|

|

Superior

Engineering |

| Our process is

built on sound principles of chemical engineering design.

To maintain premium

quality our process is carried out in glass lined reactors

and glass extraction units. We use a dedicated plant

and a separate building unit. |

| |

|

Safety

Requirements |

| Please see the

MSDS for health and safety requirements. |

| All peroxides

are high energy compounds and are inherently unstable.

Care should, therefore, be taken in handling and storage of

these compounds. |

| Kerox ME-50 is

flammable, although the risk of auto-ignition under normal

conditions is small due to its high flash point. Once

ignited it will burn slowly at first, then vigorously, and

finally explode. |

| Kerox ME-50 may

undergo slow decomposition at room temperature with

evolution of gaseous products which readily support

combustion if ignited. The gassing will also lead to

pressure build-up leading to a possible bursting of the

container. |

| Kerox ME-50 is

also catalytically decomposed by certain metallic, organic,

or acidic materials. |

| |

|

Handling Spills |

| Care must be

exercised while mopping up spillages on the production

floor. Cotton based rags or other mopping material

may, at times, be contaminated with accelerators or solvents

like acetone, which are commonly used for cleaning

operations. For the same reason, rags contaminated

with catalyst should not be thrown carelessly into waste

bins where, even in the absence of an accelerator, it may

undergo spontaneous combustion. The best way to

dispose off the contaminated rags is by burning under

controlled conditions. Each country had different

regulations and we urge you to consult accordingly for

dispoal of such waste. |

| |

|

Handling Fire |

| In the event of

an accidental fire immediately call your local emergency

response governmental department. As a first response

in such situations please be advised that conventional

carbon dioxide type extinguishers will be ineffective as the

catalyst produces its own oxygen to support combustion.

In such circumstances, the burning catalyst must be cooled

with water, wet-sand or earth, foam based extinguishers or,

if available, dry ice. All effort must be made to put out

the fire before it goes out of control. |

|

| |

|

Literature and

Links |

|

|

| |

|

Kerox ME-50 MEKP

Catalyst Specifications |

|

Compostion |

: |

Methyl Ethyl Ketone Peroxide

in phthalate plasticizer. |

|

Appearance |

: |

Clear, colorless, slightly

viscous liquid. |

|

Odor |

: |

Sharp, pungent. |

|

Peroxide Content (%) |

: |

50 ± 3 |

|

Active Oxygen |

: |

9 ± 3 |

|

Specific Gravity at 25o

C |

: |

1.08 |

|

Critical Temperature |

: |

80o C |

|

Flash Point |

: |

Above 60o C |

|

Solubility |

: |

Slightly soluble in water;

freely soluble in most organic solvens. |

|

Shelf Life |

: |

Not less than 3 months if

stored bleow 25o C. |

|

Storage Conditions |

: |

Store in cool place and do

not expose to direct sunlight. |

|

Standard Packing |

: |

1 Liter, 5 Liter, 30 Liter,

35 Liter Plastic Containers. |

|

| |

|

Practical Safety

Guidelines |

Considering the

relatively high hazad of organic peroxides, the

safety-in-use record of Kerox ME-50 has been most

satisfactory. However, careful attention must be given

to the following precautions while storing and handling of

Kerox ME-50. Considering the

relatively high hazad of organic peroxides, the

safety-in-use record of Kerox ME-50 has been most

satisfactory. However, careful attention must be given

to the following precautions while storing and handling of

Kerox ME-50. |

|

Store in a

cool, dark place. |

|

Avoid rough

handling. |

|

Keep away

from direct sunlight, steam pipes, naked flame, and

other sources of heat. |

|

Smoking

should be strictly prohibited in the vicinity. |

|

All

electrical installations should be flame proof type and

all wiring must be concealed. |

|

Avoid

contamination with metallic, organic, or acidic

materials, and in particular metal soaps and

accelerators. |

|

Avoid

contamination with solvents like acetone which may react

to form explosive mixtures. |

|

Do not store

accelerators and resins along with the catalyst. |

|

Avoid

contact with flammable materials such as wood, paper,

fabrics, saw dust, and other cellulosic materials. |

|

Keep the

catalyst in original containers. Do not return

unused material to the container. Keep the

container closed at all times to avoid contamination. |

|

Vent the

catalyst periodically to release any internal pressure. |

|

Large

quantities of catalyst, above 50 Kg, must be stored in

an isolated building away from other combustible

materials. |

|

|

| |

|

Certified

Quality |

| Kerox has been

awarded the ISO 9001:2000 certification by UKAS (UK) and

ANSI-RAB (USA) for the manufacture of ME-50 Methyl Ethyl

Ketone Peroxide Catalyst. |

| |

|

Quality Alert |

| We maintain the

highest quality in our ME-50 product. Water

contamination is a cheap diluent that is being used in other

spurious MEKP products in the market. This has highly

detrimental effects and leads to poor curing and blistering

in finished FRP composities, due to moisture migration.

Kerox ME-50 MEKP Catalyst is moisture free due to our

superior manufacturing process.

Please contact us for a water contamination test kit to test

your MEKP on site -

keroxoffice@kerox.org. |

| |

|

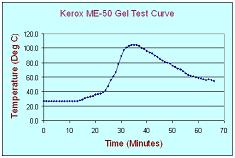

Gel Test Curves |

|

| This is a

typical gel time curve using 2% of ME-50 and 2% of C-20

Accelerator, on the weight of the resin. Gel time is

about 16 minutes and the peak exotherm is about 104o

C at about 35 minutes. The ambient temperature for

this test was controlled at 25o C |

| |

|

Recommendations |

| Gel time is a

function of the type and quantity of MEKP catalyst used,

Accelerator used, resin system, and the ambient temperature.

You can adjust these variable to alter the gel time.

Please see

literature for further insights. |

| |

|

Storage and

Handling |

| Kerox ME-50

shows no loss of activity after 3 months if kept at 25o

C. When stored above this temperature it may suffer a

slight loss of activity. Storage stability can be

considerably improved by storing at lower temperatures.

The optimum storage temperature is considered to be 10o

C. The peroxide may crystallize below 10o C

forming shock-sensitive crystals. |

| |

|

First Aid

Measures |

Kerox ME-50 is

a powerful oxidizing agent and care must be taken to avoid

contact with skin, eyes, and clothing. Protective

gloves must be worn when handling the catalyst. Kerox ME-50 is

a powerful oxidizing agent and care must be taken to avoid

contact with skin, eyes, and clothing. Protective

gloves must be worn when handling the catalyst. |

|

Skin - Immediately remove any

contaminated clothing. Wash contaminated area with

soap and a running stream of water for a minimum of 15

minutes. If irritation, or burns, or adverse symptoms

develop seek medical attention. |

|

Eyes - Serious damage can occur

if the catalyst enters the eye. As a first aid

measure, if wearing contact lenses, remove them immediately.

Flush eyes with water for at least 15 minutes.

Separate the eye lids with your finger and continue thorough

flushing. If irritation, or burns, or adverse symptoms

develop seek medical attention. |

|

Ingestion - Do not induce

vomiting. Immediately seek medical attention and

consult a physician and a poison control specialist. |

|

Inhalation - Remove affected

individual to fresh air. If coughing, breathing

becomes labored, irritation develops, or other symptoms

develop, seek medical attention at once. Even if

symptoms develop several hours after exposure consult a

physician. |

|