|

EzFloMix™ - Kerox Universal Pigments |

|

Benefits for Coloring Composites |

|

|

|

Overview: |

EzFloMix™ - Kerox Universal Pigments is an advanced single colorant dispersion

that colors ALL three of the most important resin systems used in the

manufacture of Composites and Reinforced Plastics Industry (FRP):

Polyester Resins

Epoxy Resins

Polyurethane Resins

Click for a PDF version of the EzFloMix™ brochure.

|

|

|

|

|

|

Technology Breakthrough: |

|

Pigment concentrates are essentially a dispersion of inorganic and organic color

particles in a suitable vehicle. Traditionally the vehicles are resins

that are compatible with the system it is being used with. Historically

polyester resins were colored with pigments dispersed in a polyester vehicle,

epoxy resins with an epoxy vehicle and polyurethanes with a polyurethane vehicle.

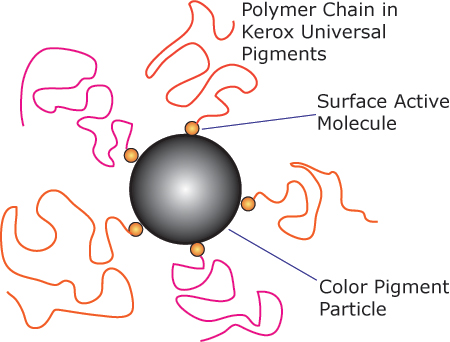

The key technology breakthrough for EzFloMix™ Kerox Universal Pigments was the

engineering of a multi-compatible polymer resin, through the incorporation of

surface active molecules into the polymer chain. These surface active

molecules attach to the color pigment particles by London-van der Waal

attractive forces. Stabilization between pigment particles takes place by

Steric Effects between the polymer chains.

The new polymer chain with surface active molecules have an excellent affinity

for all three of the commercial polymer resin systems - Polyester, Epoxy and

Polyurethane. It's through ingenious application of Physical and Reactive

Chemistry that this product is a market reality.

|

|

|

|

|

|

|

Performance Benefits: |

|

|

|

Low Viscosity, Easy Flow, Easy Mixing |

|

Kerox Universal Pigments have low viscosity. This makes the product flowable

straight out of the jar. This convenience enables the end user to add the

pigment to their resin systems easily and accurately. A further benefit is the

quick and fast mixing of the pigment into the polyester/epoxy/polyurethane

resins. The surface active molecules in the color dispersions polymeric chains

makes this possible. These advantages decrease manufacturing time and increase

the overall productivity.

Carbon Blacks, Phthalo Blues, Phthalo Greens, Organic Reds, Yellows and Violets

are notoriously difficult to disperse, because of their small particle size and

large surface area. This results in thick pastes for legacy pigment dispersions.

The EzFloMix technology from Kerox solves this problem. You don’t have to deal

with thick and difficult to handle pastes anymore, just pour and mix our

flowable colorants. |

|

|

|

|

|

Dispersion Color Stability |

EzFloMix™ Kerox Universal Pigments have excellent color stability, uniformity and

zero color separation. The color hues don't change whether

you use unfilled or filled resin systems.

|

|

|

|

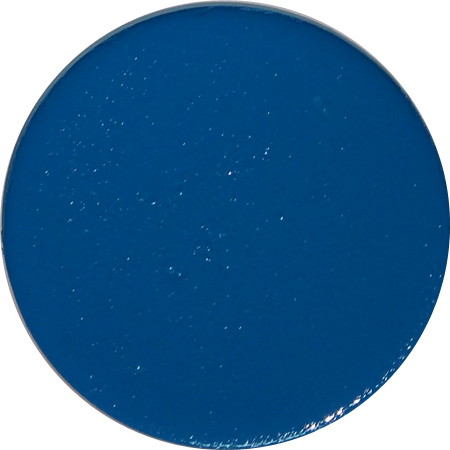

EzFloMix™ - coloring with a blend of titanium dioxide white and phthalo blue

dispersed in a polyester resin casting at 10% usage. Castings are uniform

in color and exhibit zero color separation. Though phthalo blue has a

lower density than titanium dioxide, EzFloMix™ technology ensures uniform color

dispersion and uniformity. |

Without EzFloMix™ technology, legacy pigment with same composition of titanium

dioxide and phthalo blue dispersed in a polyester resin casting at 10% usage.

Flooding and Floating is seen with phthalo blue rising to the top. The

lower density phthalo blue floats to the surface and the heavier titanium

dioxide sinks. Castings exhibit color separation and non-uniform coloring. |

|

|

EzFloMix™ - Color Uniformity and Zero Color Separtion

Another illustration showing the same EzFloMix pigment (right) blend dispersed in a polyester resin casting (left) and a gelcoat casting (middle) at 10% usage. Observe that there is no color separation and both castings have the same color hue.

|

Legacy Pigments - Flooding, Floating & Color Hue Variation

Without EzFloMix™ technology see that the same blend of pigment (right) gives completely different coloring in a polyester resin casting (left) and a gelcoat casting (middle). Poor pigment formulations, such as these, cause lighter phthalo blue to float and denser titanium dioxide to sink, thereby resulting in different color hues in different systems.

|

|

|

|

|

High Coloring Coverage and Enhanced Gloss |

|

EzFloMix™ Kerox Universal Pigments are formulated with high pigment loading.

From a manufacturing perspective, this means that you can achieve a high

coverage, which is coloring area per unit weight of pigment (grams of pigment /

square foot of coloring). Further, the EzFloMix™ technology renders the

coloring with enhanced gloss. |

|

|

|

|

|

|

|

Illustration - Kerox has been manufacturing pigments for over 50 years. On

the left is our historic thick paste 312 PO Red Pigment casting made at 10%

pigment usage on the polyester resin. With the evolution into the EzFloMix™

technology, we have successfully maintained a high pigment loading. The

same 312 PO Red Pigment with EzFloMix™ technology gives a casting (middle) which

has identical hue, again at 10% pigment usage on the polyester resin. This

shows that EzFloMix™, with its decreased viscosity, continues to give high

coloring coverage. To further demonstrate its impressive coloring

coverage, a casting (right) made with EzFloMix 312 PO Red Pigment at just 5%

pigment usage on the polyester resin, performs exceeding well. |

|

|

|

Gloss is a key attribute of EzFloMix™ Kerox Universal Pigments and below is a

snippet of actual castings made at 10% usage on the polymer resin. |

|

|

|

|

|

|

|

Outdoor Ultraviolet (UV), Indoor and Heat Stability Benefits: |

EzFloMix™ Kerox Universal Pigments have been evaluated for Outdoor Ultraviolet

(UV), Indoor and Heat Stability tests.

The stability parameters are a direct function of the inorganic and organic

pigments used in the manufacture of EzFloMix™. The following stability

properties have been published for each of our colors through careful analysis

of technical literature and laboratory tests:

Indoor Test : These are lightfastness tests carried out under

simulated conditions in a carbon arc or xenon lamp fadeometer. The exposure time

is 72-80 hours.

Outdoor Test: In these tests pigmented panels are exposed to

the sunlight in Florida, USA, positioned at 45° and facing south. The ratings

are for a 12 month exposure. |

|

Heat 15' : In this test the pigment is applied to a metal plate

made of either steel or aluminum and then exposed to a temperature of 150° C for

15 minutes.

Heat 30' : In this test the pigment is applied to a metal plate

made of either steel or aluminum and then exposed to a temperature of 150° C for

30 minutes.

The data is presented in terms of the following scales: 8 = No Bleed or

Discoloration; 6 = Slight; 4 = Appreciable; 2 = Excessive.

Since the range of colors we manufacture is very large, please email us at

sales@kerox.org to obtain the data

values for your requirement. |

|

|

|

|

|

|

Health, Safety and Environmental Benefits: |

Kerox has been producing Pigments for the Composites and FRP industry for about

50 years. During this time we have evolved with the changing technology

requirements and Health and Safety regulations globally.

The 60000 Compliance Range colors provide an elegant choice of colors for your

production requirements.

The 60000 Compliance Range colors are compliant with European Union regulations

REACH (EC No. 1907/2006) and RoHS (EU Directive 2002/95/EC) and US regulations

by OSHA (29 U.S.C. § 651 et seq. 1970) and EPA (CFR 40, 29, 21).

Products made using this range of colors will meet the requirements of the |

|

US

Clean Air Act (CAA), Clean Water Act (CWA), Federal Food, Drug and Cosmetics Act

(FFDCA), Resource Conservation and Recovery Act (RCRA), Safe Drinking Water Act

(SDWA) and Toxic Substances Control Act (TSCA).

The 60000 Compliance Range colors are free from Heavy Metals, banned Azo and

Arylamine compounds, banned Phthalates, PCB’s, Chlorinated Benzenes and

Toluenes, Pesticides and banned Flame Retardants.

Superior research and engineering by Kerox will continue to provide the market

with practical solutions to complex regulations and global standards.

|

|

|

|

|

|

|

Inventory Benefits: |

EzFloMix™ Kerox Universal Pigments are color concentrates with a long storage

life. Our product warranty is for 12 months. However, since does not

have any self polymerizable components, its practical storage life can run into

years.

Composites and FRP manufacturing technologies produce products as per market

demand. As such, a pre-blended resin with color, has its limitations.

For example, consider a large Composites

manufacturing Company, holding a large

inventory of colored polyester gelocat, or colored epoxy system for flooring, or

colored polyurethane system for castings. What happens if the color

changes from white to grey? The entire inventory becomes unusable for

producing market products.

For smaller Composites and FRP companies, pre-colored resin inventory is

impractical for market requirements. The color is dependent on customer

requirements. |

|

Incorporating EzFloMix™ Kerox Universal Pigments in the inventory mitigates this

problem. The smaller inventory enables the manufacturer to hold a variety

of colors in stock. This smaller quantity of color inventory can readily

color any clear polyester resin/gelcoat, epoxy resin or polyurethane resin.

Thereby, it facilitates a harmony between practical production and market

requirements.

In summary, EzFloMix™ Kerox Universal Pigments offers the following inventory

benefits:

Lower Inventory - More color choices for

manufacturing

Longer Storage Life - Years compared to months for gelcoats

Lower Cost - Small quantity to stock versus large quantity for

pre-colored resins |

|

|

|

|

|

|

Customer Service Benefits: |

Kerox has served the Composites and FRP industry for over 50 years. During

this time we have solved a multitude of industrial coloring challenges and

market requirement challenges. We are an ISO 9001:2000 Company and have

quality management systems in place. From our decades of experience in

this business we offer the following customer service benefits:

Large Volume Usage - Supply in MT per order in bulk or small packaging

Small Volume Usage - Supply in small packaging (1 Oz, 2 Oz, 250 ml, 600

ml jars) |

|

World Wide Shipment - Track record of 20 years to the US market and 40

years to the Asian market

Custom Color Development - Routine development of custom colors and

industry standards such as RAL

Technology Support - We share our industry coloring expertise with all

our customers

Regulatory Support - We offer full support with SDS, MSDS and other

documents to meet regulatory requirements |

|

|

|